The Rise of Cobots: How Collaborative Robots Are Transforming Small-Scale Manufacturing

Cobots: Your New Best Work Buddies

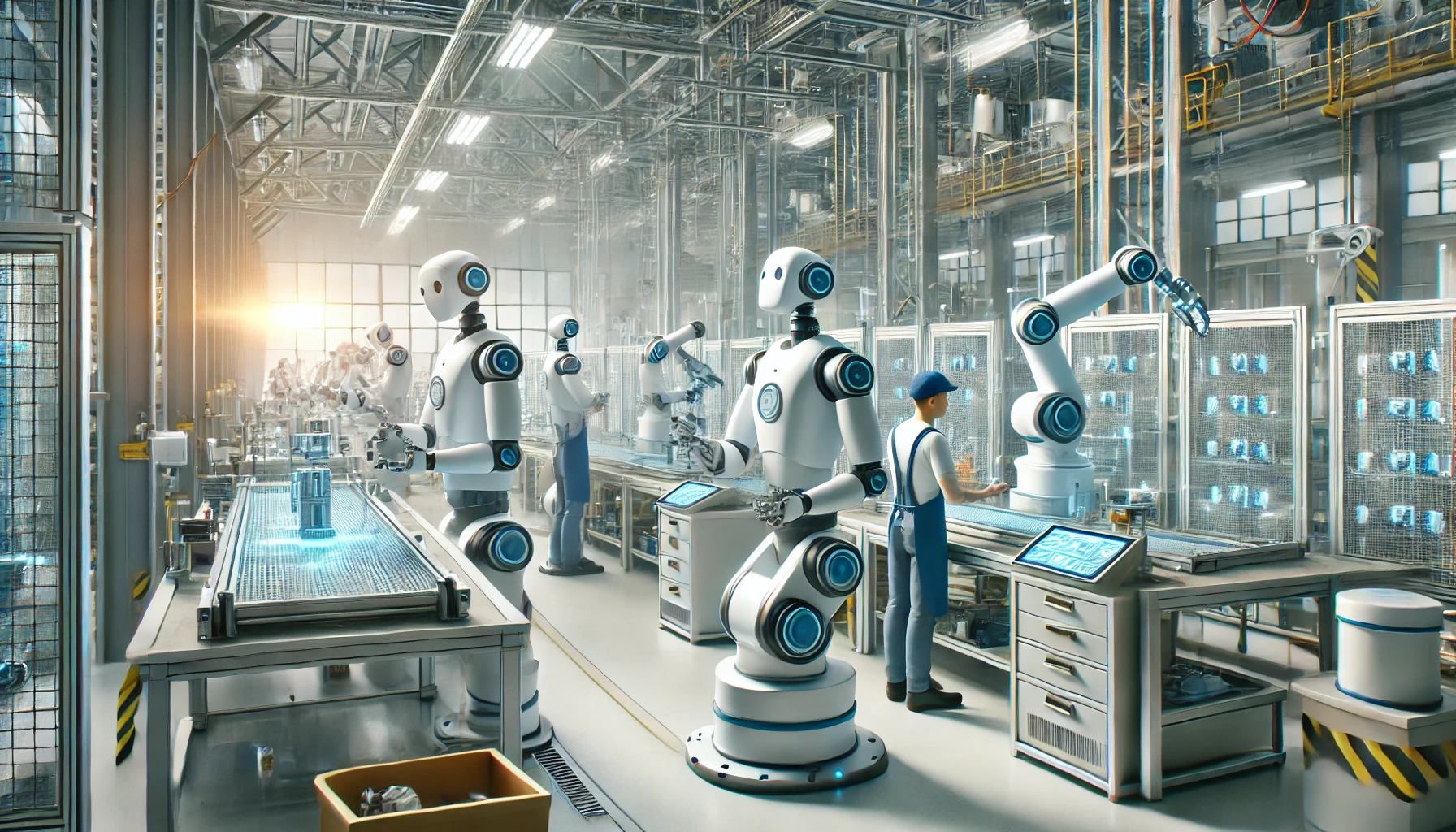

Gone are the days when robots were confined to big, impersonal factories behind protective cages. Today, collaborative robots—known as cobots—are stepping onto the manufacturing floor, and they're making waves, especially for small and medium-sized enterprises (SMEs). Cobots are designed to work safely alongside humans, assisting with tasks that are too repetitive, dangerous, or precise for us mere mortals. Think of them as the super chill coworkers who take over the monotonous stuff so you can focus on more creative and complex tasks.

The Superpowers of Cobots

Cobots come with some impressive abilities. They can assemble components with more precision than a human could ever manage, inspect products for quality control with advanced vision systems, and even handle machine tending like it’s no big deal. Plus, they have this magical ability to work quickly while still being incredibly accurate—kind of like that one guy at work who gets everything done way ahead of time but still goes for coffee breaks. And guess what? They don’t even need sleep!

Why SMEs Love Cobots

For small and medium-sized enterprises, cobots are a game-changer. Traditional industrial robots used to be too expensive and cumbersome for smaller companies, but cobots? They’re affordable, easy to program, and require minimal setup time. It’s like upgrading from a dial-up modem to fiber optic internet overnight. Many SMEs are using cobots to handle jobs like product assembly, packaging, and even machine maintenance. A small electronics manufacturer reported a 30% increase in production speed after adopting cobots without needing to hire more employees. The ROI practically speaks for itself.

Integration Challenges and Solutions

Of course, it’s not all rainbows and sunshine. Integrating cobots into an existing workflow can still be tricky. Many SMEs face challenges such as the initial investment, workforce training, and the need for task-specific customization. But fear not—many cobot manufacturers are making this process easier with user-friendly interfaces and programming tools that require zero coding experience. Plus, cobots are constantly evolving, with new features like machine learning and IoT connectivity that make them even more adaptable to changing business needs.

What’s Next for Cobots?

As technology continues to advance, the future of cobots looks incredibly bright. We’re talking about AI-driven cobots that can predict maintenance needs, adjust to new tasks on the fly, and seamlessly communicate with other machines in a smart factory setup. In the not-so-distant future, we might see cobots handling even more complex operations, allowing small businesses to scale up without the usual growing pains. The best part? All of this comes without the need for massive investments, which makes it perfect for SMEs looking to stay competitive.

So, Should You Invest in Cobots?

If you're running a small or medium-sized business and want to boost productivity, improve safety, and enhance quality control, cobots might just be the ticket. With their flexibility, ease of use, and increasing affordability, they’re no longer just tools for big corporations. So the question is, are you ready to let cobots take the mundane tasks off your hands and free up your time for bigger, better things?

The Big Question: What Will You Do with Your Extra Time?

Now that cobots are stepping in to handle the grunt work, what will you focus on next? Innovation? Expansion? Or maybe just finally taking that long-overdue vacation?